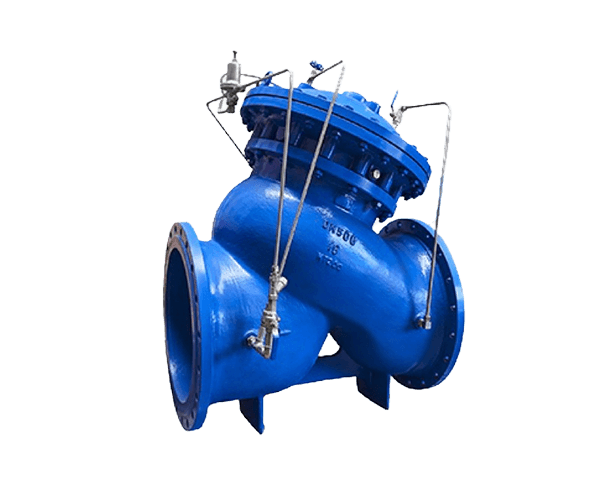

JD745X multifunctional pump control valve working principle and use instructions

JD745X multifunctional pump control valve working principle and use instructions

I. Uses

Multifunctional pump control valve is mainly used to install in high-rise building water supply system and other water supply system pump outlet pipeline, to prevent backflow of media, to prevent water hammer and water hammer phenomenon, a valve and electric valve, check valve and water hammer eliminator three functions, can effectively improve the safety and reliability of the water supply system, in line with the requirements of water supply engineering equipment mechanization and automation.

II. Features

1. Good effect of eliminating water hammer. Integrate the technical principles of slow-opening, quick-closing and slow-closing to eliminate water hammer, preventing the generation of water hammer when opening and stopping the pump.

2. Convenient operation. Only need to operate the pump motor open and close button, the valve is in accordance with the pump operating procedures to realize automatic opening and closing.

3. Good energy-saving effect. The valve body adopts streamlined direct-flow design, small pressure loss, large flow rate, and small size and light weight.

4. The valve has a double-chamber drive mechanism, divided into two different pressure chambers, which is characterized by a smooth water stop closure without pressure fluctuations. In addition, the entire drive mechanism can be disassembled as a unit without removing the diaphragm, thus facilitating inspection.

II. Main technical parameters

1、Working pressure: 1.0Mpa, 1.6Mpa, 2.5Mpa

2、Applicable media: raw water, water, oil and the nature of the liquid close to water

3、Medium temperature:0~80℃

4、Acting pressure: ≤0.05Mpa

5、Slow-close time:3~60S(Adjustable)

6、Water hammer peak: ≤1.3 times the working pressure

7、Maximum reversal speed of water pump: ≤1.2 times the rated speed of the water pump

8, resistance loss: than the swing check valve to reduce 31%

9、Structural form: diaphragm type

IV. Application criteria

Quality Assurance: ISO9000 Structure Length: GB/T 12221

Test standard: GB/T13927 ISO5208

Design standard:JB/T 10674 Flange standard:GB/T 17241.6 GB/T9113.1

V. Main structure and external dimensions

1、Body 2、Stem 3、Seat 4、Large flap 5、Small flap 6、Ball valve (gate valve) 7、Middle bonnet 8、Diaphragm 9、Diaphragm platen 10、Strainer 11、Upper bonnet 12、Micro-check valve 13、Strainer 14、Ball valve (gate valve)

Notes:Due to product improvement there may be differences between the physical and promotional material data, the company does not give notice, the company reserves the right to interpret the above data.

VI. Principle of operation

Multifunctional pump control valve is mainly composed of main valve and conduit control system. (Refer to the structure diagram) The main valve consists of valve body, valve cover, valve stem, size valve flap and diaphragm, diaphragm pressure plate and so on. Among them, the upper and middle valve cover, valve stem, diaphragm, diaphragm pressure plate and small valve is connected as a whole, the diaphragm will be divided into two different pressure chamber called double chamber drive mechanism. The large valve flap can slide up and down on the valve stem. The conduit control system consists of ball valves, micro check valves, filters and piping. Part of the conduit control system connects the main valve inlet with the lower chamber of the control chamber, and the other part connects the main valve outlet with the upper chamber of the control chamber. The valve is closed before leaving the factory.

When the pump starts, the pressure of the main valve inlet rises, and the pressure water enters the lower chamber of the control room through the ball valve (14), filter (13), and micro-check valve (12), which pushes the diaphragm platen upward and drives the small flap to open, and the large flap opens at the same time with the small flap under the impetus of the water flow to complete the opening of the valve. At the same time, the water in the upper chamber of the control chamber flows through the filter (10), ball valve (6) to the main valve outlet. Due to the micro check valve (12) of the throttling effect, the opening speed of the small valve flap is slower, to ensure that the main valve opening time is greater than the start time of the pump motor, to realize the light-loaded start the pump, to avoid excessive speed due to the opening of the valve to produce the opening of the pump water hammer.

When the pump is turned off, the main valve inlet pressure is lower than the outlet pressure, the large valve flap under the action of gravity, quickly fall closed, cut off about 90% of water flow. At the same time, the main valve outlet pressure water into the upper chamber of the control room, pushing the diaphragm pressure plate downward, so that the small valve flap closure, and ultimately realize the complete closure of the main valve. By adjusting the opening of the ball valve (6) at the outlet end of the main valve, the downward speed of the diaphragm pressure plate can be controlled to realize the slow closure of the small valve flap, effectively eliminating the water hammer of the stopped pump.

VII. Installation Precautions

mounting

1, before installation, please check whether the main valve parts are intact, fasteners are complete, no loosening.

2. Check that the connecting piping is in good condition and the joints are tight.

3、 A gate valve and a filter should be installed before the valve, and a gate valve should be installed after the valve to facilitate maintenance.

4. The best way to install the valve is to install it on the horizontal pipeline with the valve cover facing up. If the valve is installed in the shade well, there should be a certain space for technicians to overhaul;.

5, installation, pay attention to the valve body outside the water flow marked arrows, follow the direction of installation.

6, used for fire protection system should be started regularly to check to prevent the production of scale, resulting in valve failure.

caveat

1, lifting and handling shall not collide, damage to the external piping accessories.

2, the valve inlet end shall not be installed flexible joints or pipe expanders;; and

3, pipeline installation should be installed in accordance with the relevant norms to install automatic exhaust valves to ensure that there is no interruption of the water column.

4, before installation to thoroughly remove debris in the pipeline, water must be thoroughly flushed before the pipeline;.

5, there is a possibility of water hammer hazards of the pumping station, should be stopped pump water hammer calculations;.

6, must be installed in accordance with the relevant specification requirements for maintenance valves.

VIII. Commissioning steps

1, check whether the valve installation direction, position is correct;

2, open the main valve inlet and outlet pipe end ball valves (14), (6);

3, start the pump, the main valve should be able to open slowly. If the opening speed of the valve is too fast, it should be replaced with a micro check valve with a smaller throttling hole, or temporarily adjust the opening of the ball valve (14) at the inlet end to reduce the opening speed.

4, stop the pump slow closing time can be adjusted by adjusting the main valve outlet end of the ball valve (6) to adjust the degree of opening, should be the first control valve to adjust the small, to extend the slow closing time. If the slow closure time is too long, the ball valve (6) of the opening increased; if the slow closure time is too short, the ball valve (6) of the opening can be adjusted down.

Nine, common faults and treatment methods

Failure phenomenon cause of the failure to deal with the method

| fault phenomenon | Reason for failure | Treatment |

| The main valve won't open. | 1, the main valve inlet and outlet end of the pipeline blockage, or ball valve is not open 2、 Micro check valve is damaged, clogged 3、 Pre-valve pressure is too low | 1、 Clean the pipeline, open the ball valve 2. Replacement of micro check valves 3. Increase pump head

|

| Main valve not closing tightly | 1, the main valve inlet and outlet end of the pipeline blockage, or ball valve is not open 2、 Micro check valve is damaged, clogged 3、 There is a foreign body in the valve 4、 Damaged seals | 1、 Clean the pipeline, open the ball valve 2. Replacement of micro check valves 3. Removal of foreign objects 4. Replacement of seals |

| Open the valve too fast | 1、 Micro check valve restriction hole is too large 2、 There is air in the pipe | 1. Replace the micro check valve with a smaller restrictor hole. 2. Regular evacuation of gas |

Installation Diagram